Remaining focused on protecting supply chains, keeping production at full capacity to meet demand, and adapting to transformations in technology, trends towards automation, and new operation methods is crucial for the future. An optimally running facility depends on factory staff, floor supervisors, and security personnel having critical information with immediacy to prevent disruptions in production and keep employees and assets safe throughout day-to-day operations.

Alert-to-Action

Security Solution for Factories and Manufacturing Plants

See what you need, when you need it.

Protection of the production process to maintain full capacity

Event Response for the Factory Floor

For factories and manufacturing facilities, keeping production schedules on track is crucial not only for the success of the business, but also for the contribution to the greater economy afforded by the goods and materials produced. Loss of production time adversely affects factory output and for some industries, disruptions could lead to even further impact on essential functions and availability of supplies to the populace. Video monitoring can be used as a measure to protect the production process in ways such as tracking inventory levels, following arrivals and shipments in real time, and visually supervising overall operations and the production floor. With trends towards automation and the conscious efforts to minimise close contact between staff on-site, keeping eyes on critical areas at all times presents factories and manufacturing facilities with challenges that necessitate a need for real-time notifications to optimise operations.

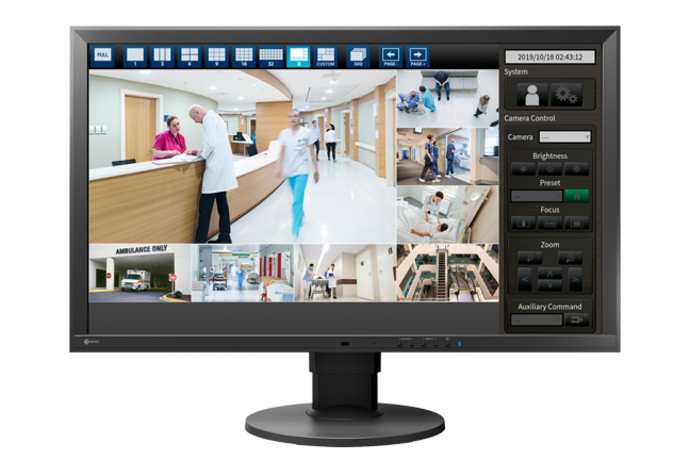

EIZO’s IP video decoding solutions support customizable integration with security, video analytics, and access control systems with the Alert-to-Action function. This means that the monitor or IP decoding box itself can serve as a two-way communication device and provide alert notifications directly to factory staff or floor supervisors in response to specific events.

For example, IP cameras and video analytics or certain machine vision cameras, can detect abnormal conditions in the production line, machinery malfunctions or overheating, or monitor the flow of people and product throughout the plant and send an alert. The monitor or IP box solution can be programmed to automatically adjust the layout, enlarge the screen, or apply visual indicators, such as a text message or frame, to actively notify staff when it receives an alert.

A command can also be sent from the IP monitor or decoding box to a signal light on the production floor to quickly draw the attention of on-site staff to a specific location for assessment. This helps manufacturing supervisors stay informed when there is an issue and take the necessary actions to resolve it before production is heavily disrupted or halted completely. Furthermore, factories that employ “lights-out manufacturing” – in other words factories that are fully automated and require little to no human intervention – can take advantage of an integrated alert system with EIZO’s solution, so if there is a malfunction or outage, off-site personnel can be notified to immediately to take action.

Mitigate Risks and Workplace Hazards to Keep Employees Safe

Visibility in High-Risk Environments

High-risk machinery, hazardous material handling, towing vehicles, and other high-risk mechanisms may contribute to accidents in the workplace. Securing the environment to keep employees safe and protected is of the utmost priority. Among the most common accidents in these settings are falls or contact with objects or equipment that result in injury. Workplace accidents also directly impact the production process, which may need to be halted if an incident occurs.

When integrated with a video management system (VMS), video analytics, or other security systems, EIZO’s IP decoding solutions can take a more proactive role in protecting factory employees by enabling intervention to prevent dangerous incidents and quick response in the event of an accident. With Alert-to-Action, the monitor can provide visual indicators when cameras or life safety systems detect a fall, if staff enters a restricted or unsafe zone, such as those with machinery or moving parts, or if machinery malfunctions or exhibits unsafe levels of operation. This allows operators and factory staff to quickly take action to ensure the environment remains safe and secure. Proactively mitigating workplace hazards not only keeps staff safe, but also helps to prevent disruptions in production due to downtime caused by an incident.

Protecting Equipment, Assets, and Intellectual Property

Safeguard Sites 24/7

Factories and manufacturing facilities are often a target for theft due to the value of materials, equipment, and machinery stored on site. Not only physical assets, but production process methods, intellectual property, and trade secrets must also be closely safeguarded. Factory sites need to have methods to defend against intrusion in order to protect the business, maintain production schedules, and keep production costs down.

When integrated with the local access control system, EIZO’s IP decoding solutions can take a more proactive role in protecting factory property. With the Alert-to-Action function, the IP monitor or decoding box can visually communicate if unauthorized person enters the premises or restricted areas, such as storage areas, or server rooms, if suspicious persons exhibit odd behavior, or if equipment has been tampered with. A surveillance camera can utilize presence detection technology to send an alert to the monitor which can automatically change the layout or add a visual indicator to the screen, notifying security personnel immediately. Furthermore, a command can also be sent from the IP monitor or decoding box to activate an audio warning through an audio security system to deter intruders before any damage is done and protecting the premises remotely.

For certain products and industries, such as those relating to food, drugs, chemicals, etc., it is imperative for manufacturing sites to also protect their materials from environmental conditions. Systems with environment sensors, such as those that measure temperature and humidity in an area, are used to ensure sensitive components, perishable goods, and other materials are properly quality controlled and safely stored until they can be used in production. If abnormal environmental conditions or contamination are detected, the installed system can send an alert to the IP monitor or box, which can then display a visual indicator for the active supervisor to act. Integrating these and other systems into the visual communication framework allows for quick and reliable verification of stored material and inventory status.

Solution: Alert-to-Action

Customizable event response

EIZO’s IP decoding solutions’ web API supports custom integration with the local security systems and devices to allow communication with and response to alerts over the network. When an event occurs and an alert is sent from IP cameras, access control, hazard detection, VMS, or other systems, EIZO’s solution responds with a preassigned action, such as layout adjustment, message display, audio activation, camera adjustment, masking, and more. Implementing an intelligent visual communication system into the workflow is a step forward in future-proofing security systems burdened with a high volume of information for factory staff and management to optimise day-to-day operations. Optimising the security & surveillance system with smart event response ensures these facilities provide a safe and efficiently moving production or manufacturing environment for prosperous business and contribution to the economy.